Oracle EBS R12 – Inventory Setting Up Organizations

Setting Up Organizations

Responsibility: Inventory, Vision Operations USA

1. Navigate to the Organizations window.

- (N) > Setup > Organizations > Organizations.

2. (B) New in Find window

3. Set up a new organization using the following information:

- Name: M12 Orlando MFG

- Type: Plant

- Location: M12 Orlando MFG

4. Save your work.

5. In the Organization Classifications alternative region, select the following information:

- Name: Inventory Organization

- Enabled: Selected

6. Save your work.

Define Accounting Information

7. (B) Others > Accounting Information.

8. Enter the following accounting information:

- Primary Ledger: Vision Operations

- Legal Entity: Vision Operations

- Operating Unit: Vision Operations

9. Save your work.

Define Inventory Parameters

10. (B) Others > Inventory Information > (T) Inventory Parameters

11. Enter the following inventory parameters:

- Organization Code: M12

- Item Master Organization: Vision Operations

- Calendar: Vision01

- Demand Class: Blank

- Move Order Timeout Period: 60 Days

- Mover Order Timeout Action: Approve automatically

- Locator Control: Determined at Subinventory Level

- Allow Negative Balances: Selected

-

Auto Delete Allocations at Move Order Cancel: Selected

Instructor Note: Discuss the different types of organizations, Manufacturing Partner Organization, EAM Enabled, Process Manufacturing Enabled, WMS Enabled, and WCS Enabled.

12. (T) Costing Information

13. Enter the following costing parameters:

- Costing Method: Standard

- Transfer to GL: Yes

- Reverse Encumbrance: No

- Project Cost Collect Enabled: No

- Defer Logical Transactions: No

- Cost Cutoff Date: Blank

- Default Material Sub-Element: Blank

- Material Overhead Sub-Element: Blank

14. Enter the following valuation accounts:

|

Account Type |

Account |

|

Material |

01-000-1410-0000-000 |

|

Outside Processing |

01-000-1450-0000-000 |

|

Material Overhead |

01-000-1420-0000-000 |

|

Overhead |

01-000-1430-0000-000 |

|

Resource |

01-000-1440-0000-000 |

|

Expense |

01-520-7530-0000-000 |

15. Other Accounts

16. Enter the following other account information:

|

Account Type |

Account |

|

Purchase Price Variance |

01-520-5210-0000-000 |

|

Invoice Price Variance |

01-520-5220-0000-000 |

|

Inventory AP Accrual |

01-000-2220-0000-000 |

|

Sales |

01-520-4110-0000-000 |

|

Cost of Goods Sold Account |

01-450-5110-0000-000 |

17. (T) Revision, Lot, Serial And LPN

18. Enter A in the Starting Revision field.

19. Enter the following Lot Control parameters:

- Uniqueness: Across Items

- Generation: At Item Level

- – Total Length: 30

- Auto Create Lot UOM Conversion: Blank

- Allow Different Lot Status: With exception

20. Enter the following Serial Control parameters:

- Uniqueness: Within organization

- Generation: At organization level

- Prefix SER

- Starting Serial Number: 0000000001

21. ATP, Pick, Item-Sourcing

22. Enter the following information:

- ATP Defaults Rule: Total ATP, No DC (select second)

- Picking Defaults: Rule: Default Picking Rule PR1

- Subinventory Order: Blank

- Locator Order: Blank

- Pick Confirmation Required: Blank

- Over Picking for Manufacturing: Blank

- Over Picking for Transfer Orders: Selected

- Enable Rules Override for Lot-Level Res.: Selected

- Item Sourcing Detail: Type: Supplier

- Item Sourcing Detail: Organization: Blank

- Item Sourcing Detail: Subinventory: Blank

23. (T) Inter-org Information

24. Enter the following information:

- Inter-organization Transfer Charge: Predefined percent

- Predefined Percent: 10%

- Transfer Credit: 01-520-5290-0000-000

- Purchase Price Variance: 01-520-5210-0000-000

- Receivable: 01-000-1810-0000-000

- Payable: 01-000-2370-0000-000

- Intransit Inventory 01-000-1460-0000-000

25. (M) File > Close Form

Define Receiving Information

26. (B) Others > Receiving Information

27. Enter the following Receiving Information:

- Enforce Ship-To: None

- ASN Control Action: None

- Receipt Days Early and Late: 5

- Receipt Days Exceed-Action Warning

- Over Receipt Tolerance (%) 5%

- Over Receipt Action Warning

- RMA Receipt Routing: Standard

- Receipt Routing: Standard

- Allow Substitute Receipts: Selected

- Allow Unordered Receipts: Selected

- Allow Express Transactions: Selected

- Allow Cascade Transactions: Selected

- Validate Serial Numbers on RMA Receipts: Selected

- Receipt Number Generation: Automatic

- Receipt Number Type: Alphanumeric

- Next Receipt Number: 1

- Validate Lots on RMA Receipts: Restricted

- Receiving Inventory Account: 01-000-1410-0000-000

- Clearing Account: 01-000-1410-0000-000

28. (B) Save

29. Click Close Window.

30. Save your work.

31. Close the Organizations window.

Link the Location to the Inventory Organization

32. Navigate to the Location window.

- (N) Setup > Organizations > Locations

33. Find M12 Orlando.

- (M) > View > Query By Example > Enter

34. Enter %M12% in the Name field.

- (M) > View > Query By Example > Run

35. (T) Other Details

36. Enter the following information:

- Inventory Organization: M12 Orlando MFG

37. Save your work and close the window.

Practice – Generating and Maintaining Serial Numbers

Overview

In this practice, you will learn how to update your revision, lot, and serial control for your items. You will also learn how to receive items into stock that have revision, lot, and serial control. You will use the items you created in the Defining Items practice.

Instructor Note: Serial Numbers are unique within inventory items and are generated at the item level.

Assumptions

- You are skilled in Oracle Navigation.

- You have completed the Defining Items practice.

- You must have access to an Oracle Application Vision database or comparable training or test instance at your site on which to complete this practice.

- Responsibility: Inventory, Vision Operations USA

Tasks

Generate Serial Numbers

1. Predefine a range of serial numbers using the following information:

- Item: ##-Item07 then (B) OK

- Quantity: 10000

Note: ## represents your team number.

Find Serial Numbers

2. Find the serial numbers you generated. What state are the serial numbers in?

_______________________________________________________

Maintaining Serial Numbers

Responsibility = Inventory, Vision Operations USA

Generate Serial Numbers

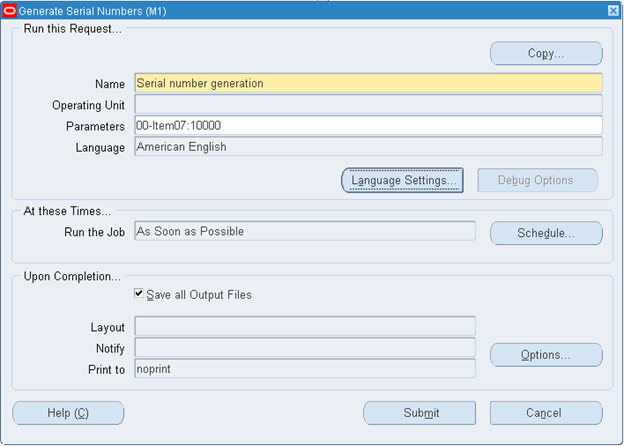

1. Navigate to the Generate Serial Numbers window.

- (N) On-hand, Availability > Generate Serial Numbers

2. Enter the following information:

- Item: ##- Item-07

- Quantity: 10000

3. (B) OK

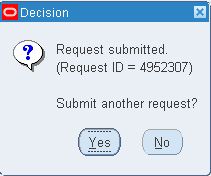

4. (B) Submit

5. (B) No

Find Serial Numbers

Instructor Note: You can mention from this window that the student can view serial genealogy as well as transaction information.

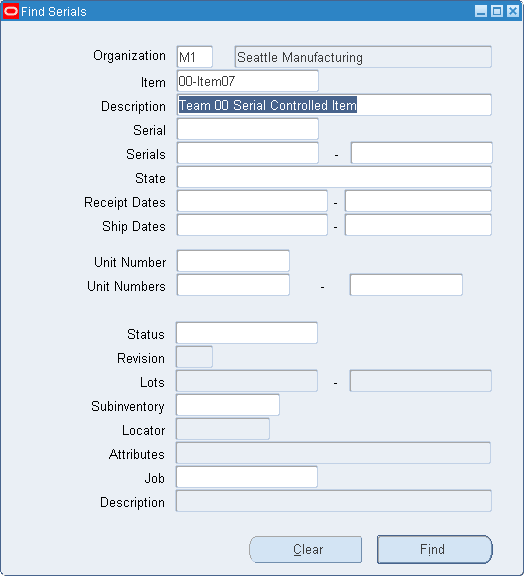

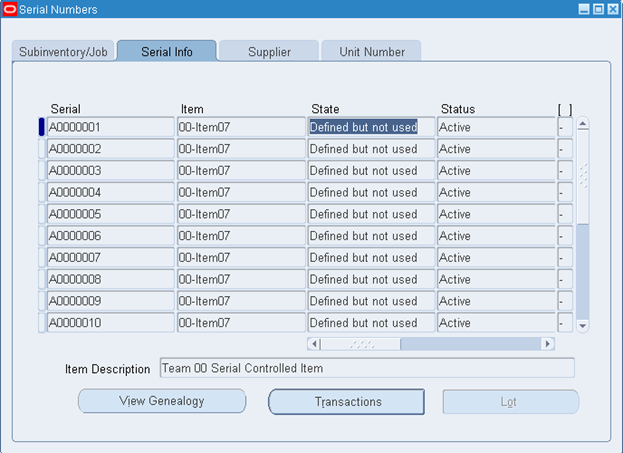

6. Navigate to the Serial Numbers window.

- (N) On-hand, Availability > Serial Numbers

7. Enter the following information:

- Item: ##-Item07

If you place your cursor in the item field then you can enter information in that field.

8. (B) Find

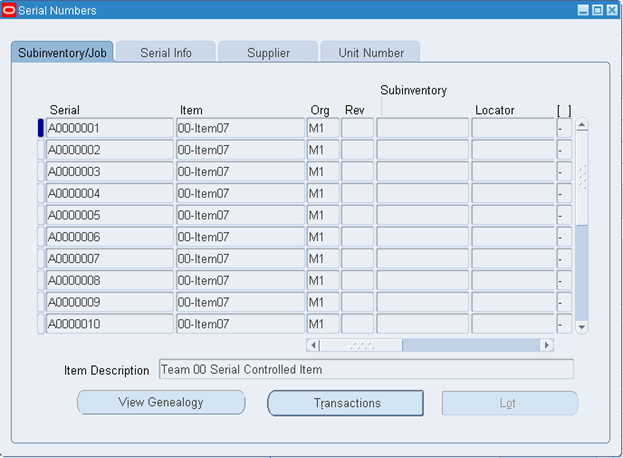

9. (T) Serial Info

The serials are in the Defined but not used state.

10. (M) File > Close Form