Oracle Inventory : Using Material Workbench, Reservation & Status Control

Practice – Using the Material Workbench

Distribution

Oracle Inventory

Job Title*

Ownership

The Job Title [list@YourCompany.com?Subject=LABxxxxx] is responsible for ensuring that this document is necessary and that it reflects actual practice.

Practice – Using the Material Workbench

Overview

In this practice you will use the Material Workbench to view the on-hand quantity for your an item.

Assumptions

- You must have access to an Oracle Application Vision database or comparable training or test instance at your site on which to complete this practice.

Tasks

Use the Material Workbench to view all On-hand Quantity in a Subinventory

1. Use the Material Workbench to view all items in your ##FGI subinventory and note the quantities.

Solution – Using the Material Workbench

Use the Material Workbench to view all On-hand Quantity in a Subinventory

Responsibility: Inventory, Vision Operations USA

1. Navigate to the Material workbench

- (N) On-hand, Availability > On-hand Quantity

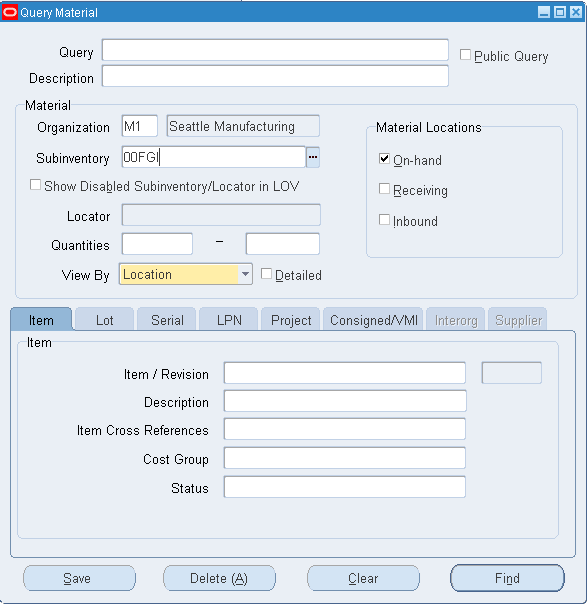

2. Enter the following information:

- Organization: M1

- Subinventory: ##FGI

- On-hand: Selected

- View by: Location

3. (B) Find

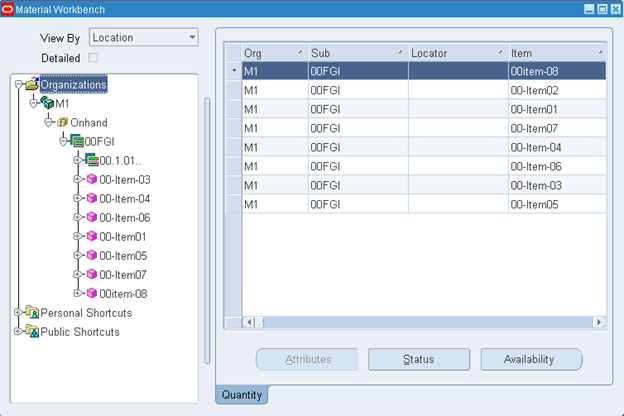

4. Click Organizations

5. Click M1

6. Click Onhand

7. Select Item ##-03 in the right pane.

8. (B) Availability

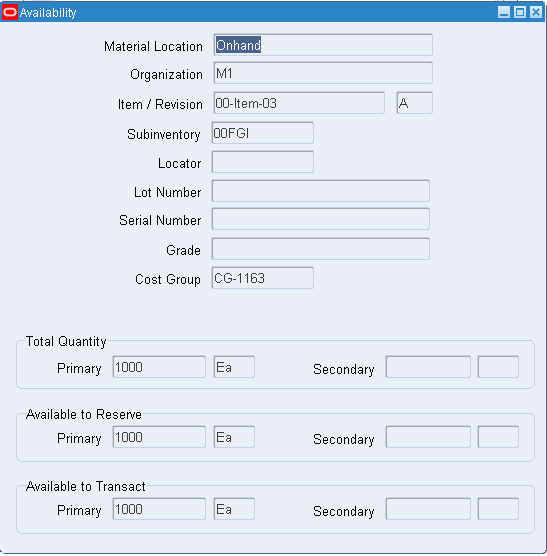

9. What is the total quantity? _______________________________________

10. What is the available to reserve quantity? _____________________________

11. What is the available to transact quantity? _____________________________

- (M) File > Close Form

- Optional: Create and save a Query that lists items with quantity on hand less than zero.

Guided Demonstration – Using the Material Workbench

Responsibility: Inventory, Vision Operations USA

1. Navigate to the Material Workbench

- (N) On-hand, Availability > On-hand Quantity

2. Enter the following information:

- Receiving: Deselected

- Inbound: Selected

- On-hand Deselected

Instructor Note: Explain the purpose of the different tabs to the students.

3. (B) Find

4. Click Organizations

5. Click M1

6. Click Inbound

7. Click Purchase Order to view all incoming purchase orders.

8. Click the top purchase order to view information about the purchase.

9. (B) Availability

10. (M) File > Close Form

11. (M) File > Close Form

Creating Reservations

In this practice, you will create a reservation for one of your items.

Tasks

Create a Reservation

1. Use the following information to create a reservation:

- Organization: M1 Seattle Manufacturing

- Item: ##-Item02

- Type: Inventory

- Name: Team ## Reservation

- Need By Date: Today’s Date

- Quantity: 10

Solution – Creating Reservations

Create a Reservation

Responsibility = Inventory, Vision Operations

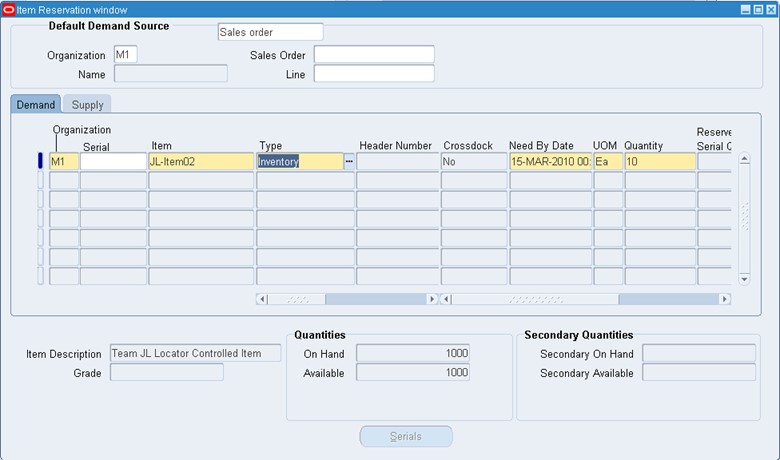

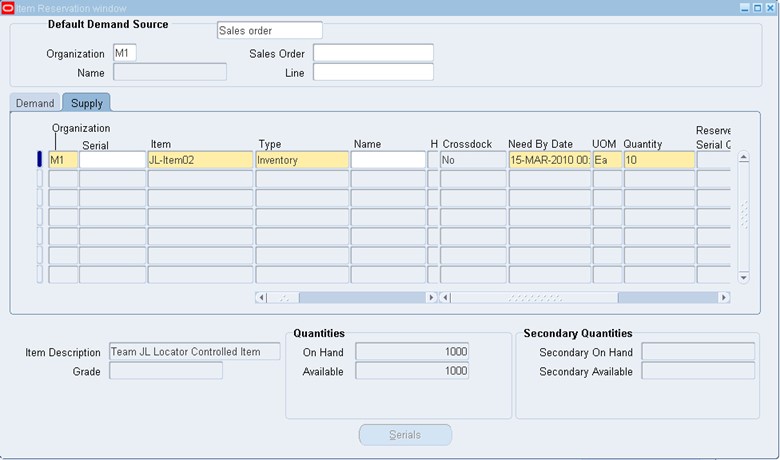

1. Navigate to the Item Reservation window.

- (N) On-hand, Availability > Reservations

2. (B) New

3. Enter the following Demand information:

- Organization: M1

- Item: ##-Item02

- Type: Inventory

- Name: Team ## Reservation

- Need by date: Today’s date

- UOM: Ea

- Quantity: 10

4. (T) Supply

5. Enter the following Supply information:

- Type: Inventory

- Name: Team ## Reservation

6. (B) Save

7. (M) File > Close Form

Creating Reservations

Responsibility: Order Management Super User, Vision Operations USA

Instructor Note: Verify that item AS10000 is enabled for M1 Seattle manufacturing, and that quantity of it exists in the FGI, subinventories within M1 Seattle.

Explain to the students that creating a sales order is a function of Oracle Order Management, and that they will not be learning how to book a sales order.

1. Navigate to the Sales Orders window.

- (N) Orders, Returns > Sales Orders

2. (T) Order Information

3. Enter the following order-header information:

- Customer: AT&T Universal Card

Note: The rest of the required information defaults automatically.

4. (T) Line Items

5. Enter the following line-item information:

- Ordered Item: AS10000

- Qty: 10

- Request Date: Greater than 30 days from today’s date

- Promise Date: Greater than 30 days from today’s date (found on Shipping Tab)

6. (T) Shipping

7. Verify the following shipping information:

- Warehouse: M1

- Source Type: Internal

8. Note your sales order number and line number_____________________________

9. (B) Book Order

10. (M) File > Close Form

11. Navigate to the Reservations window.

- (N) Inventory > On-hand Availability > Reservations

12. (B) New

13. (T) Demand

14. Enter the following demand information:

- Organization: M1

- Item: AS10000

- Type: Sales Order

- Header Number: Your sales order number

- Line Number: Your sales order line number

15. (M) File > Tools > Select Available Inventory

Note: You could enter enough quantity to satisfy the demand from multiple subinventories in the Selected Reservation Qty field. For example, you could select 8 from the FGI subinventory, and 2 from another subinventory. In this case, that’s not possible since quantity only exists for AS10000 in FGI.

16. (B) Done

Note: Oracle Inventory generates a new reservation for each inventory selection you make.

17. (M) File > Save

18. (M) File > Close Form

Setting up Material Status Control

In this practice you learn how to set up and use material status control.

Tasks

Verify Transaction Type

1. Verify that the following Subinventory Transfer Transaction type is set for status control.

Define a Material Status

2. Define a material status to be used only for subinventories that disallows subinventory transfers. Use the following naming convention for your material status. Team ## Material Status, where ## represents your team number.

Assign a Material Status

3. Assign your material status to your low value subinventory. (##LV).

Perform a Transaction with Your Material Status

4. Use the following information to perform a miscellaneous receipt:

- Item: ##-Item01

- Subinventory: ##LV

- Quantity: 15

- Account: 01-580-7740-0000-000

5. Attempt to perform a subinventory transfer for material in your ##LV subinventory.

Can you perform the subinventory transfer? _________________________________

Solution – Setting up Material Status Control

Verify Transaction Type

Responsibility: Inventory, Vision Operations

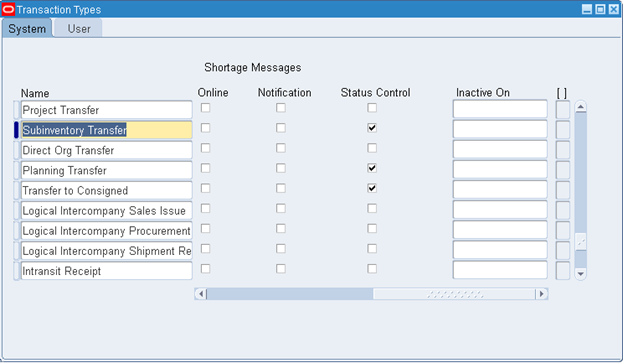

1. Navigate to the Transaction Types window.

- (N) Setup > Transactions > Types

2. (T) System

3. Verify that Status Control is selected for the Subinventory Transfer transaction type.

4. (M) File > Close Form

Define a Material Status

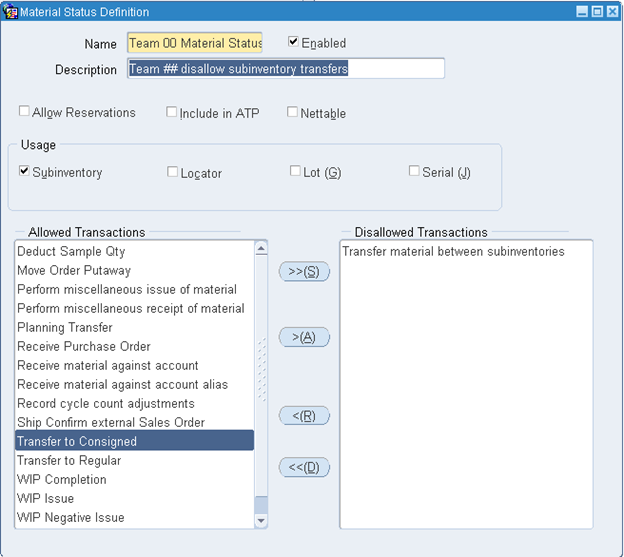

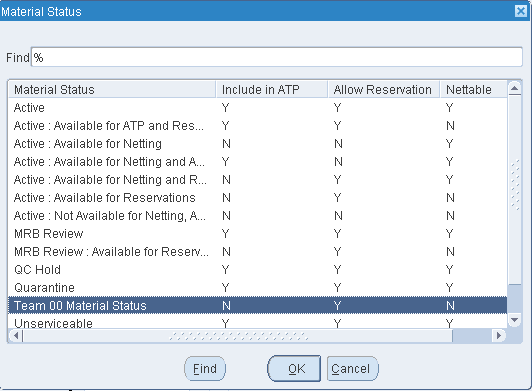

5. Navigate to the Material Status Definition window.

- (N) Setup > Transactions > Material Status

6. Enter the following information:

- Name: Team ## Material Status

- Description: Team ## disallow subinventory transfers

- Usage: Subinventory

7. Select Transfer material between subinventories from the Allowed Transactions list.

8. (B) >(A)

9. (M) File > Save

10. (M) File > Close Form

Assign a Material Status

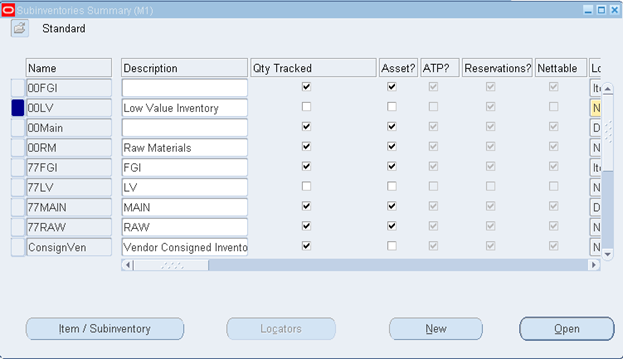

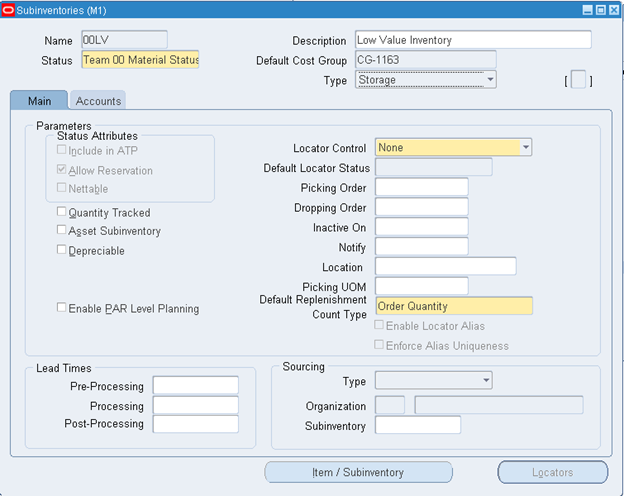

11. Navigate to the Subinventories Summary window.

- (N) Setup > Organizations > Subinventories

12. Select your ##LV Subinventory.

13. (B) Open

14. Select your material status.

15. (B) OK

16. (M) File > Save

17. (M) File > Close Form

18. (M) File > Close Form

Perform a Transaction with Your Material Status

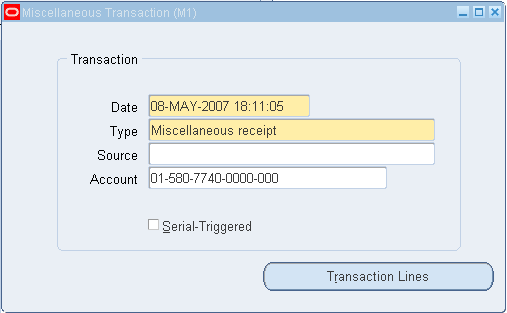

19. Navigate to the Miscellaneous Transactions window.

- (N) Transactions > Miscellaneous Transaction

20. Enter the following information:

- Type: Miscellaneous Receipt

- Account: 01-580-7740-0000-000

21. (B) Transaction Lines

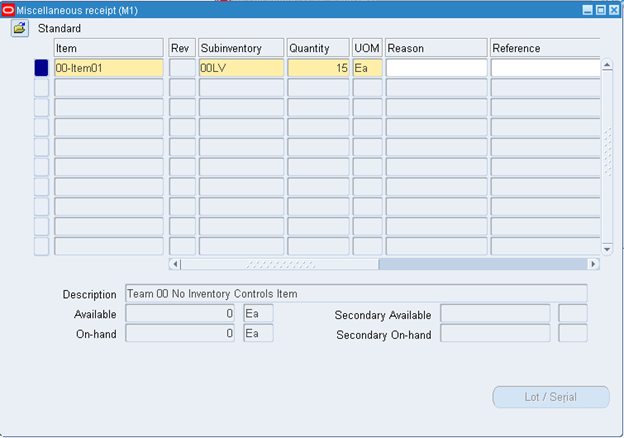

22. Enter the following information:

- Item: ##-Item01

- Subinventory: ##LV

- Quantity: 15

23. (M) File > Save

24. (M) File > Close Form

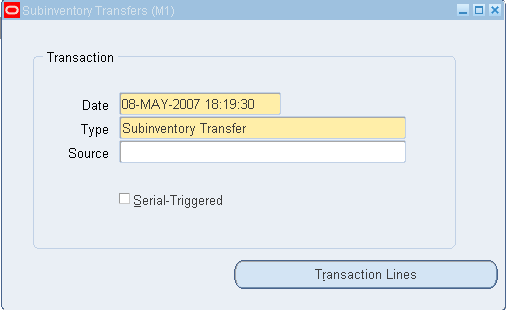

25. Navigate to the Subinventory Transfers window.

- (N) Transactions > Subinventory Transfer

26. Enter the following information:

- Type: Subinventory Transfer

27. (B) Transaction Lines

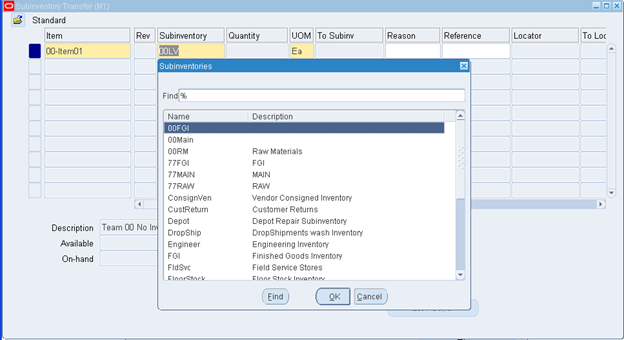

28. Enter the following information:

- Item: ##-Item01

- Subinventory: ##LV

Can you perform subinventory transfer? No, ##LV is missing from the list of subinventories.

Why is ##LV missing from the list of Subinventories? ____________________

29. (B) Cancel

30. (M) Edit > Clear > Record

31. (M) File > Close Form

32. (M) File > Close Form